After two years of intensive research and development, RedBOND introduces the new RedBOND Advanced to the large format digital printing market. It is a unique product worldwide with very high digital printing features, endorsed by the certification of the American multinational HP.

Madrid, December 17,2020.- RedBOND, a Grupo Aliberico’s company specialized in the production of aluminium panels for digital printing, has launched the new product RedBOND Advanced, the first and only aluminium composite panel worldwide that has managed to be certified by HP for its latex inks.

RedBOND Advanced is the result of two intense years of research and development work carried out by a technical and multidisciplinary team that has included technicians from Alucoat Conversion, specialists in lacquering aluminium coils, and professionals from HP, a specialized American company in printing technologies.

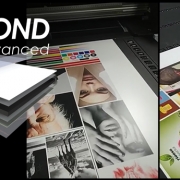

The new RedBOND Advanced manages to solve the printing problems of this type of formats, achieving a much more vivid printing finishes, in which the images seem to come alive. In addition, thanks to its technology, the inks adhere uniformly and with great force to the surface, avoiding any detachment of the ink on the panel. The results have been collated in various technologies and manufacturers of large format printers, as well as in latex technology, the ecological alternative to conventional solvent ink, developed by HP.

The unique characteristics of RedBOND Advanced, which have allowed it to be the first and only aluminium composite panel in the world to be certified by HP for its latex inks, resistant to water and without emitting harmful odors, and the fact that it is made of aluminium, infinitely recyclable material, make this product the most environmentally friendly solution (SDG 13).

About RedBOND

Located in Alicante, and with a strategy based on research and technological innovation, RedBOND has revolutionized the sector of aluminium composite panels for digital printing, to the point of having reduced its delivery times to just two weeks.

The company exports more than 90% of its production, supplying mainly to the European and North African markets, and will soon do so also to the North American market.

Since the beginning of its operations in 2012, the company has not stopped growing, having tripled its turnover in the last 4 years and doubled its workforce and production capacity through various investments. In addition, it has recently acquired land for the construction of a second factory in Alicante.